You may have seen the words Tencel and Lyocell being used interchangeably many times. In this article, we are going to debunk all the myths and learn completely about Tencel fabrics.

Table of Content:

- What is Tencel Fabric?

- What is Tencel Fabric made of?

– Preparing the wood pulp

– Washing the pulp

– Dissolving the cellulose

– Filtering

– Spinning

– Washing the fiber

– Drying

– Carding

– Finishing - What is Tencel fabric used for?

- Is Tencel fabric sustainable?

- Tencel fabric manufacturers in India

- Tencel Vs Cotton?

- What are the main characteristics of Tencel fabric?

What is Tencel Fabric?

In 1972, the largest rayon fabric manufacturer ‘American Enka’ first developed a fiber called Lyocell. It is a semi-synthetic fabric that is commonly used as a substitute for cotton or silk. The objective for the development of Lyocell was to find out a sustainable material to replace synthetic fiber like polyester.

But within a few years, the project was abandoned by the company for some unknown reasons. At this time around, the abandoned project was taken up by the research team at a British company named Courtaulds Fibers in the 1980s. They are responsible for creating Tencel. It is a fiber developed on lyocell research. Thus we can say that both these fibers have identical chemical structures. Hence these names are used interchangeably.

What is Tencel fabric made of?

Now we know that Tencel is a branded version of Lyocell. But how is it made? There are nine steps involved in the production of Tencel.

- Preparing the wood pulp:

The raw material required for the development of Tencel is sourced sustainably from forests. Hardwood like birch or eucalyptus trees is used for this purpose. The trees are broken down into small chips, cleaned, and then loaded into a chemical batch in order to turn the chips into wood pulp.

- Washing the pulp:

Once the wood turns into a pulp, it is then washed and bleached in order to kill the bacteria and sanitize the material properly. Then, it is dried on a sheet and rolled in spools.

- Dissolving the cellulose:

The dried sheets are cut into smaller squares and then placed in a pressurized and heated vat of amine oxide.

- Filtering:

In the vats, the cellulose dissolves into a clear liquid. This clear liquid is filtered and pumped through spinnerets.

- Spinning:

Spinning is the process of turning the liquid into long and thin fibers. When the clear liquid is forced through spinnerets, it is turned into fibers.

- Washing the fibers:

The resulting product will be unfinished Tencel fiber. It is then immersed in a vat of diluted amine oxide to set, and they are then washed with demineralized water.

- Drying:

The fibers are then dried and a lubricant such as silicone or soap is applied.

- Carding:

The carding process separated and orders the fiber strands.

- Finishing:

In this final step, the fibers are cut and then turned into a variety of different products.

What is Tencel Fabric used for?

More and more people around the world want to purchase products that do not cause any harm to the environment. At the same time, they also want the products to be comfortable and stylish. Tencel fabric is an answer to both. Designers, retailers, and brands around the world are using Tencel fabrics to develop various apparel products.

Brands are embracing this new material in order to bank on the new market demand. Besides, using Tencel can be an added advantage for companies while they market their product. The labels can now proudly say that the product is sustainable and eco-friendly.

Woven apparel for both men and women

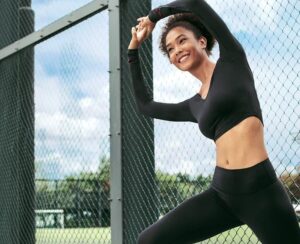

Tencel for activewear / knitted wears

Is Tencel Fabric sustainable?

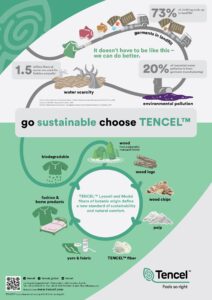

When it comes to understanding whether material is completely sustainable, we have to make sure that the entire supply chain, from sourcing to disposal, is 100% sustainable. Meaning, the production of Tencel should not harm anyone in any way whatsoever.

It is quite surprising for many users to think that Tencel is 100% sustainable. The wood required for making the fiber is actually sourced from certified farms. It is also completely biodegradable and fully compostable. Now you may wonder about the impact of the involvement of chemicals, water, and electricity.

Tencel production is taken place in a closed loop. Meaning the chemicals and water involved in the production are not wasted. It is reused and sent it back to the loop for producing more Tencel. The US Department of Agriculture has awarded Tencel the BioPreffered award. It is only given to those materials that are made using renewable materials. Besides these, it is also a patented product.

Tencel fabric manufacturers in India

Dinesh Exports manufactures various Tencel fabrics upon the client’s requirements. We are certified with multiple sustainability standard certifications like BCI Cotton certification, OEKO-TEX certification, GOTS certification, Fair Trade certification, OCS certification, and GRS certification. We are proud to be contributing to the well-being of the planet by providing our customers with a whole range of sustainable woven fabrics. For more details, please reach out to us.

Tencel Vs Cotton

If we compare cotton to Tencel, we can clearly see Tencel as the winner. It has various qualities like cotton. But better. In this age where natural resources are scarce and the environment is polluted day by day, we really want to think about replacing cotton with Tencel. Both have similar advantages like breathability, softness, versatility, and durability.

What are the main characteristics of Tencel fabric?

Besides having a high score on sustainability, Tencel fabrics also have the following:

- Soft and comfortable to wear

- Strong and durable

- Breathable, suits for both winter and summer

- Absorbs water better than cotton

- Dried faster

- Tencel shrinks and creases less than cotton

- It is extremely resistant to bacteria.

If you want us to manufacture Tencel fabrics for you or your client, please reach out here.