When sourcing fabric for your clothing line, there are a few things to keep in mind. The most important factor is the quality of the fabric. It’s essential that your fabrics are durable and can withstand multiple washing.

You’ll also want to choose fabrics that are in line with your target demographic. For example, if you’re targeting young adults, you’ll want to choose youthful and trendy fabrics.

When sourcing fabrics, it’s also important to consider the cost. You’ll want to find a balance between quality and affordability. You should also research the various types of fabrics available and find the one that best suits your needs.

There are a variety of fabrics to choose from, such as cotton, silk, linen, or wool.

Each has its own unique benefits and drawbacks.

For instance, cotton is affordable and versatile, but it can be prone to wrinkles.

Silk is often seen as a luxurious fabric, but it can be very expensive.

Linen is lightweight and breathable, but it can also be pricey.

Wool is durable and resilient, but it can be costly and difficult to care for.

When sourcing fabric for your clothing line, it’s important to find a supplier that you can trust.

Here are a few tips on how to find the right supplier:

- Do your research. There are many suppliers out there, so it’s important to do your research and find one that meets your specific needs.

- Ask around. Get recommendations from other designers or businesses in your industry.

- Look for quality fabrics. Make sure the supplier offers high-quality fabrics that will stand up to wear and tear.

- Check out their selection.

Make sure the supplier has a wide selection of fabrics to choose from.

- Get samples. It’s important to order samples before you commit to a supplier. This will allow you to see the quality of their fabrics and make sure they meet your expectations.

Types of woven fabric suppliers online

When sourcing fabric, it is important to consider the many types of suppliers available. The most common types of fabric suppliers are as follows:

– Manufacturers: Manufacturers are the primary producer of a fabric. Based on the capacity of the manufacturer, each manufacturer can be either vertically integrated or a stand-alone type of manufacturer.

The vertically integrated manufacturer will have end to end facility from farming or producing fibers to spinning, weaving, and processing.

Then the other type of fabric manufacturers is the ones that buy yarns and weave or knit the fabric at their facility.

In both these cases, the price of the fabric can only differ in small variations unlike a wholesale distributor or a retail distributor.

– Wholesalers: Wholesalers are companies that purchase fabric in bulk directly from the manufacturer.

They then sell the fabric to retailers or other businesses.

Because they buy in large quantities, wholesalers typically offer lower prices than other types of fabric suppliers.

– Distributors: Distributors are companies that purchase fabric from the manufacturer and then sell it to retailers.

They do not typically carry a large selection of fabrics, but they do offer a wide variety.

Source woven fabrics online

At Dinesh Exports, we provide online sourcing services to buyers around the globe with additional support for designing, sample development, yardages, swatches, low MOQ manufacturing, and timely delivery.

In recent times, trade shows have become a tedious process with travel restrictions and other global events making it extremely difficult for buyers to meet with new suppliers.

A buyer can easily browse through our website to have a look at various products and understand the strengths easily on their system or mobile phone.

Frequently Asked Questions in Fabric Sourcing

To get you started with sourcing fabrics in the right way, please make yourself aware of these questions as they are important to get your fabric sourcing right.

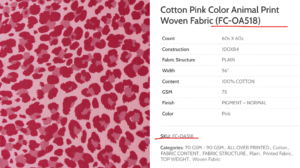

- What is the Fabric Reference number?

Each and every fabric will have a unique identifying number.

When a buyer approaches the seller for fabrics, they would send you a collection of fabrics that are similar to buyer requirements.

These are often called swatches or hangers.

In order properly communicate between the buyer and the supplier, each fabric should have a reference number.

2. What is the GSM?

GSM simply means grams per square meter.

It is calculated using a GSM calculator and helps determine the weight of the fabric.

Weight is an important factor while selecting fabric for apparel.

As the gsm is higher, the price and weight of the fabric increase.

Example: Heavier gsm fabrics are suitable for cold climates and bottom wear.

Whereas, lighter gsm fabrics are ideal for top-wear and hot climatic conditions.

Read more about GSM

3. What is the fabric composition?

Fabric composition refers to the type of fibers/yarns used for making the fabric.

Based on the material used, fabric compositions is like below:

- Uni-blend: Uniblend fabrics have only a single material as yarns. Eg: 100% cotton fabric

- Multi-blend: Multi-blend fabrics have more than one fiber content in them. Eg: 85-15 Cotton Polyester fabric (85% cotton+15% polyester)

4. What is the fabric construction?

Construction means the number of yarns in the warp and weft of the fabric.

5. What is the fabric structure?

Fabric structure represents the type of weaving style used (in woven fabrics) for making the fabric.

Read more about woven fabrics here.

6. What is the cuttable width of the fabric?

Cuttable width is the measurement across the width of the fabric roll from edge to edge.

At Dinesh Exports, we manufacture up to 61” – 63”

7. What is the Sampling price per meter/yard?

Once the buyer shows interest to manufacture fabric, they will require to receive anywhere from 2 – 100 meters of fabric to sample produce their product. The price for sampling can be higher than the bulk price because of the effort it requires to make the sample.

8. What is the MOQ (Minimum order quantity)?

The minimum order quantity is the minimum meters/yards of fabrics the buyer needs to purchase in order for the manufacturer to start production. MOQ varies depending on the manufacturer. It can vary anywhere from 200 meters to 1000 meters.

9. What is the lead time?

Lead time is the time required for the manufacturer to complete the production from order to delivery.

It can vary from 20 – 60 days.

To source woven fabrics, contact us.