Defects are indicators that determine whether a product is good or not. If a garment has a high number of defects, it is likely a lower quality garment, and if it has fewer defects, it is a higher quality garment. Definitions of defects and defective parts are discussed below.

What are Garment Defects?

Different types of garments can occur during the production process. First, let’s consider what a defect is basically. Any deviation from quality standards (QA) that affects the appearance, durability, safety or suitability of a product is called a defect.

Classifications of Garment Defects?

- Critical Defects:

This indicates that the product is unsafe or dangerous for the end user or violates mandatory regulations.

- Major Defects:

A material defect may impair the appearance or performance of the product and affect its merchantability and usability. Due to this defect, it cannot be sold as the first choice. If this defect can be repaired or eliminated, this product can be upgraded as first quality.

- Minor Defects:

If the product has a minor defect, this kind of product can be marketed and used, but it will lose its standard quality. Due to these types of defects, the product does not meet defined specifications or quality standards.

Types of Garment Defects

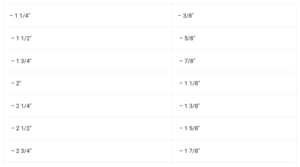

- Fit and measurement defect:

After crossing a certain limit of garments measurement, there will be a defect. There are defined measurements of all parts of garments. I have made an example of how measurement up down expressing:

2. Construction Defects:

Defects occur when certain limits of clothing are exceeded. There are defined dimensions for every piece of clothing. I created an example of how measurements are expressed from top to bottom.

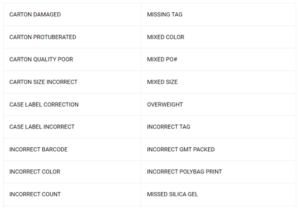

- Packing Defects:

Packing is a very important and delicate process for exporting garments. Choosing the wrong packaging material can lead to packaging defects. On the other hand, the wrong packing size is also considered as bad packing. Please be careful when packing, as there are many defects in the packaging.

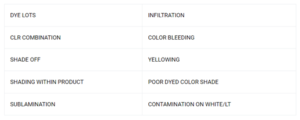

- Color Defects:

Clothing shading issues include chromatic aberration. If inappropriate shades are applied to the product. A color error is a type of visual error that causes customers to reject a product.

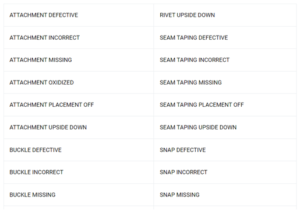

- Trims Defect:

Wrong trims and accessories are considered a trims defect.

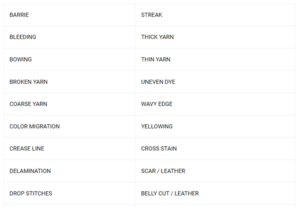

- Fabric Defects:

Garments are manufactured by using fabric. If there is any defect in the fabric then it will produce defective garments. That’s why fabric defect is sure will be visible in garments.

How to calculate Defects per Hundred Units (DHU)?

Defects per hundred units (DHU) – number of total defects in 100 checked garments. The formula for DHU:

DHU = Total no. of defects found * 100 / total pieces checked

How to calculate Percentage Defective (PD%)?

Total number of defective pieces in 100 checked garments

Percentage defective = Total no. of defective pieces * 100 / Total pieces checked

Example: Suppose on a day one table checker checked 200 pieces. He found a total of 15 defective pieces and in those 15 pieces total of 60 defects were found. So, the quality measure of that lot in terms of DHU is 30 (60*100/200) and Percentage Defective is 7.5%.

Hope this article was helpful. If you are looking for a reliable woven fabric manufacturer that follows rigorous quality checks, contact us.