TLDR

Choosing the right sewing needle size is not a small decision. The wrong needle can damage fabric, cause skipped stitches, or slow production. This guide explains common needle sizes used in garment manufacturing, how they are measured, and which fabrics they actually work best with.

In garment factories, needles are often treated like consumables. Change when it breaks, replace when stitches look bad. But needle size plays a bigger role than that. A slightly wrong size can cause fabric damage, seam puckering, yarn breakage, or even operator complaints.

If you are a merchandiser, production controller, or sourcing manager, understanding needle sizes helps you avoid quality issues before they show up in inspection. It also saves time on the floor, because the operator is not stopping every few minutes.

Check out our digital swatch here

How sewing needle sizes are measured

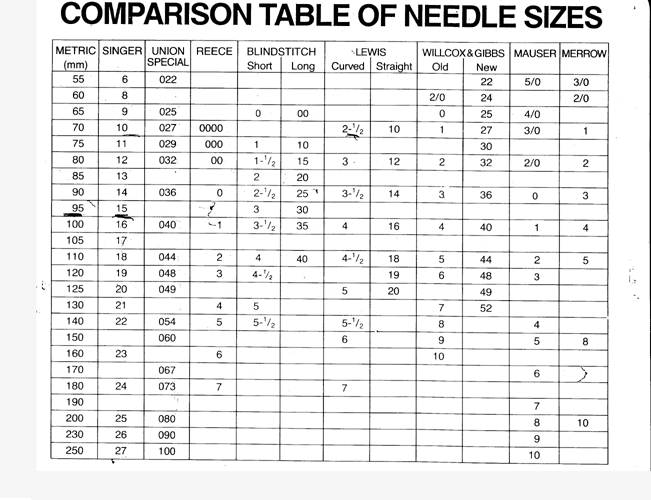

Needle sizes are usually written in two numbers, like 75/11 or 90/14. This confuses many people at first.

Here is what it actually means.

- The first number is the European size (Nm)

- The second number is the American size

Both numbers represent the diameter of the needle shaft, but in different units.

Smaller number means thinner needle. Bigger number means thicker needle.

So a 65/9 needle is much finer than a 110/18 needle.

Common needle size chart used in garment factories

Below is a simple reference that most apparel units follow. This is not theory, this is what actually gets used on the floor.

65/9

- Very lightweight fabrics

- Chiffon, voile, sheer cotton

- Mostly for sampling, not bulk

70/10

- Lightweight woven fabrics

- Cotton cambric, lawn, rayon voile

- Used in ladies tops, linings

75/11

- Light to medium fabrics

- Cotton poplin, fine twill

- Very common in shirt sampling

80/12

- Medium weight fabrics

- Cotton shirting, blended fabrics

- One of the most used needle sizes in apparel

90/14

- Medium to heavy fabrics

- Denim shirts, canvas, uniforms

- Used where fabric strength is higher

100/16

- Heavy fabrics

- Denim, duck, upholstery fabrics

- Often used in workwear production

110/18

- Very heavy materials

- Multiple layers, thick seams

- Not common in fashion garments

Matching needle size with fabric type

This is where most issues happen. Fabric looks medium weight, but yarn density is high. Or fabric is soft but tightly woven. Needle selection must consider both.

Some practical matching examples:

- Cotton poplin shirts: 75/11 or 80/12

- Cotton twill trousers: 80/12 or 90/14

- Lightweight dresses: 70/10

- Denim shirts: 90/14

- Canvas bags or aprons: 100/16

If the needle is too thick, you will see visible holes after stitching. If it is too thin, needle breakage increases.

What happens when the wrong needle size is used

This part is often ignored until defects appear.

Common problems include:

- Fabric yarns getting cut

- Seam puckering after wash

- Skipped stitches at high speed

- Thread breakage

- Needle heating and melting synthetic yarns

Many factories try to fix this by changing thread tension. But the real issue is often the needle.

Needle size vs sewing speed

Higher machine speed demands better needle selection. A thin needle running at very high speed on dense fabric will heat up faster. This leads to friction damage and poor stitch quality.

That is why industrial setups sometimes go one size thicker than sampling, especially for long production runs.

This is also why needle change schedules exist, even if the needle looks fine.

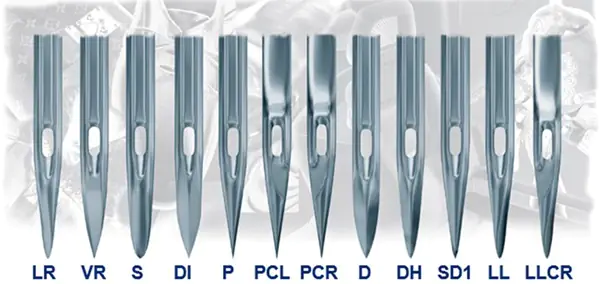

Flatbed vs special machines

Needle size also depends on machine type.

- Lockstitch machines: widest range of needle sizes

- Overlock machines: usually slightly finer needles

- Coverstitch machines: depends on fabric stretch and layers

- Buttonhole machines: specific needle types and sizes

Most factories standardize needle sizes per machine to reduce confusion.

What merchandisers should check during sampling

If you are approving samples, do not just look at fabric and fit. Ask these questions:

- What needle size was used?

- Is it the same planned for bulk?

- Any needle marks visible on light fabric?

- Does seam open after wash?

These small checks avoid surprises later.

Final thoughts from a manufacturing point of view

Needles look like the smallest part of garment making, but they touch every single piece that goes out of the factory. Getting needle size right improves seam quality, reduces rework, and keeps production stable.

For woven fabrics especially, needle selection should never be random. It should be tested, recorded, and followed consistently.

At the end of the day, good garments are not just about fabric and fit. They come from many small right decisions. Needle size is one of them.

If you are looking for a reliable woven fabric manufacturer for your garments, please contact us.