Garment manufacturing is a complex and competitive industry. To stay ahead of the competition, it is important to keep a check on the health of your garment factory. One of the most effective ways to do this is by measuring the cost per piece. In this article, we will discuss how to check the health of a garment factory using cost per piece.

Understanding Cost per Piece

Cost per piece is the total cost incurred by a factory for producing a garment. It is a key performance indicator (KPI) used to monitor profit and loss in order execution. It is highly applicable in factories that are doing job work. In that case, they are paid Cost of Making which includes cutting, sewing, finishing, and packing. Trim cost is also included sometimes if the vendor is responsible for ordering trim. The cost per piece for an order is calculated using this formula.

Cost /Piece = Cost of Making of full Order/ Total Order Qty

Garment Cost Components

To calculate the total cost incurred in an order and then calculate the cost per piece, you need to know the cost components. The primary cost components in garment costing are:

- Cost of Cutting

- Cost of Sewing

- Cost of Finishing

- Cost of Packing

- Trim Cost

- Overhead Cost (Fixed and Variable)

Order specific cost components include:

- Changeover Cost/Time

- Learning Curve and Efficiency Loss due to it

- NSR Trainings

- Testing

- Quality Training

- Operator Hire and Training

Activity-Based Costing

This is a much more realistic approach than the above two. Every activity creates a cost, and these costs can be associated directly with the product, customer, or supplier for which the activity is being done. All the factory overheads here as allocated to activity centers like design, MIS, merchandising, quality, and distribution.

Example: Cost per Piece Calculation

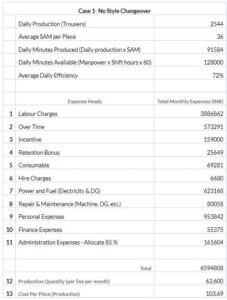

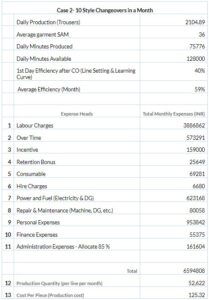

To better understand cost per piece, let’s take a hypothetical example. Here, we have taken cost elements of manufacturing and daily production. We are considering 25 days in a month.

Impact of Order Quantity and Style Changeovers on Costing

It is important to note that the style changeover is a high factor impacting manufacturing cost and productivity in a factory. In a factory, when there are smaller orders, there will be more style changeover. So, you can relate the impact of order volume on garment cost per piece.

Monitoring Cost per Piece and Line Changeover Time

Cost per piece and line changeover time need to be closely monitored. Style loading sequence must be planned by PPC so that similar styles come one after another. This will reduce the need for new machines and new skills. It will also reduce sudden jumps in manpower shortage or abundance.

Conclusion

In conclusion, checking the health of a garment factory is essential for staying competitive in the industry. By measuring cost per piece, you can get an accurate picture of the profitability of your business. It is important to monitor cost per piece and line changeover time closely and plan style loading sequences effectively. This will help reduce costs and increase productivity, ensuring the long-term health of your garment factory.

If you are looking for a reliable woven fabric manufacturer, please reach out to us.